We are thrilled to announce a significant success story for one of our Central Ohio manufacturing clients, demonstrating the immediate and dramatic impact of expert Power Factor Correction (PFC)!

The Energy Efficiency Group (of SW Ohio), in collaboration with our esteemed partners, Global Energy Solutions Group (of Indianapolis, IN) and Garber Electric (of Dayton, OH), recently completed a state-of-the-art Power Factor Correction installation. The results not only met, but immediately exceeded expectations!

The Challenge: Low Power Factor Dragging Down Efficiency

Prior to the installation, the manufacturer was operating with a challenging Power Factor (PF) of only 0.75. A low PF is a common issue for industrial facilities with heavy motor and inductive loads, leading to:

Prior to the installation, the manufacturer was operating with a challenging Power Factor (PF) of only 0.75. A low PF is a common issue for industrial facilities with heavy motor and inductive loads, leading to:

- Higher utility penalties (often called “reactive power charges”).

- Reduced system capacity (less “real” power available for production).

- Increased operating temperatures and strain on equipment.

The Solution: Expert Design and Seamless Execution

Leveraging the combined expertise of our three organizations, we designed and implemented a robust, customized Power Factor Correction system.

- Energy Efficiency Group provided the initial analysis, project management, and specialized energy engineering oversight.

- Global Energy Solutions Group supplied the advanced PFC equipment and technical configuration expertise.

- Garber Electric handled the safe, professional, and efficient electrical installation on-site.

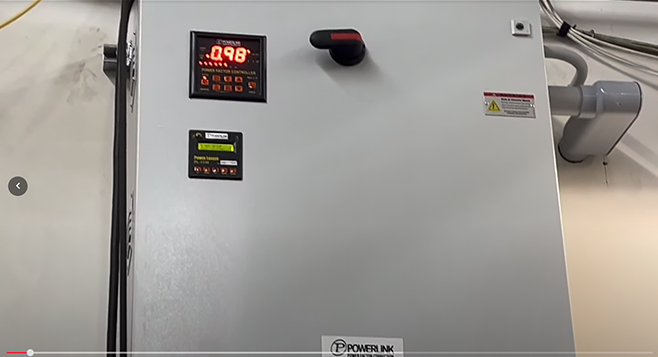

The Unbelievable Results: Near-Perfect Efficiency

The moment the system was commissioned, the client saw an incredible and immediate improvement.

The manufacturer’s Power Factor number instantly jumped from the challenging = 0.76 to an outstanding range of 0.98 – 0.99!

What does a Power Factor of 0.98-0.99 mean?

A Power Factor approaching 1.0 signifies highly efficient electricity utilization. This near-perfect result means the manufacturer is now minimizing wasted energy, eliminating utility penalties, and maximizing the capacity of their existing electrical infrastructure—leading directly to significant cost savings and improved operational stability.

This project is a perfect example of how strategic partnerships and targeted energy solutions can deliver massive, immediate value. We are proud to have delivered this level of performance to our client.

To find out what Energy Efficiency Group can do for your organization’s Power Factor, Energy Efficiency, energy billing, and sustainability efforts, contact us today!

#PowerFactorCorrection #EnergyEfficiency #Manufacturing #UtilitySavings #EnergyManagement #CentralOhio #GarberElectric #GlobalEnergySolutionsGroup #IndustrialEfficiency